Dellestraat 55

3550 Heusden-Zolder

Belgium

t. +32 (0)78 155 202

csoapsa@airproducts.com

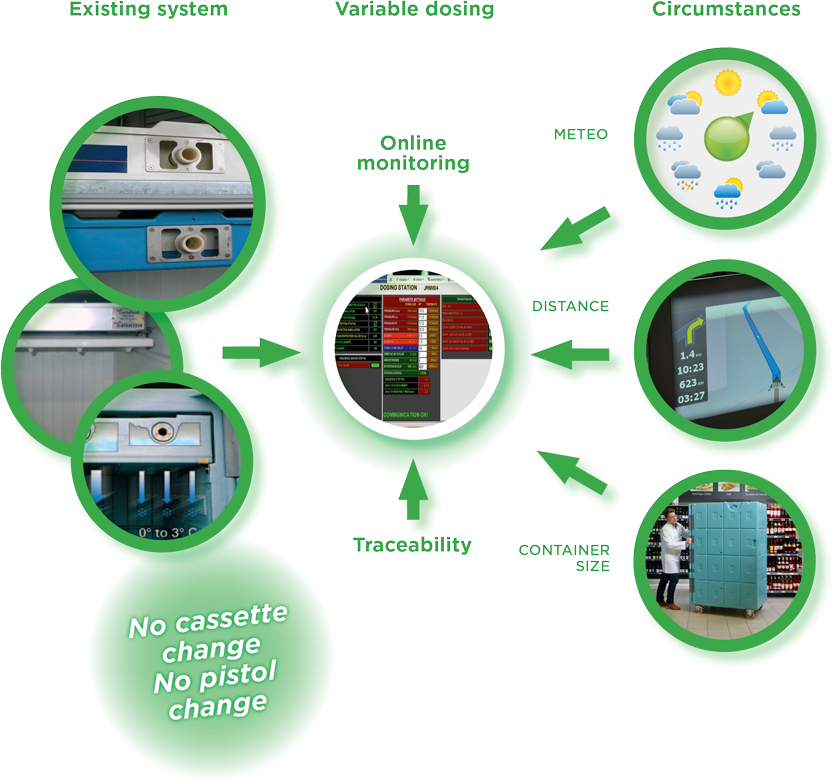

Ice-Shuttle Flex - Improvement of existing container/cassette system

Are you already using CO2 as a coolant for cold chain cooling during transport? With Ice-Shuttle Flex, ACP can optimise your current installation and help you to make significant savings in your operational costs, as well as giving you full CO2 sourcing reliability.

Whatever type of insulated container/cassette system or injection pistol/station you are using, ACP will optimise them to reduce your operational costs.

Ice-Shuttle Flex

- Set up variable dosing for your current system through a specially designed software program based on:

- Container size

- Transport time/distance

- Weather forecast (automatically integrated into the program)

- Online monitoring feature for reporting and traceability purposes

Main benefits

- Cost saving: Less CO2 thanks to reduced waste. Optimised dosing of CO2 quantity based on variable parameters: container size, transport time/distance and weather forecast

- Most reliable CO2 sourcing in Europe

- Simple switchover:

- No cassette change required

- Fast and without operational interruption

- No IP restrictions

- Limited investment as you use your existing cassettes

Furthermore:

- Suitable for frozen and fresh food

- Customisation options, such as integration into your ERP

- Data storage on ACP’s own servers, with secured Internet access

- 24/7 maintenance service

- 24/7 back-up delivery system in place

- Telemetry on the CO2 tanks enables GPRS-driven level tracking